Cast Coil Transformer Dry Type

Keywords:

Cast Coil Transformer Dry Type

Category:

产品描述

- 产品描述

-

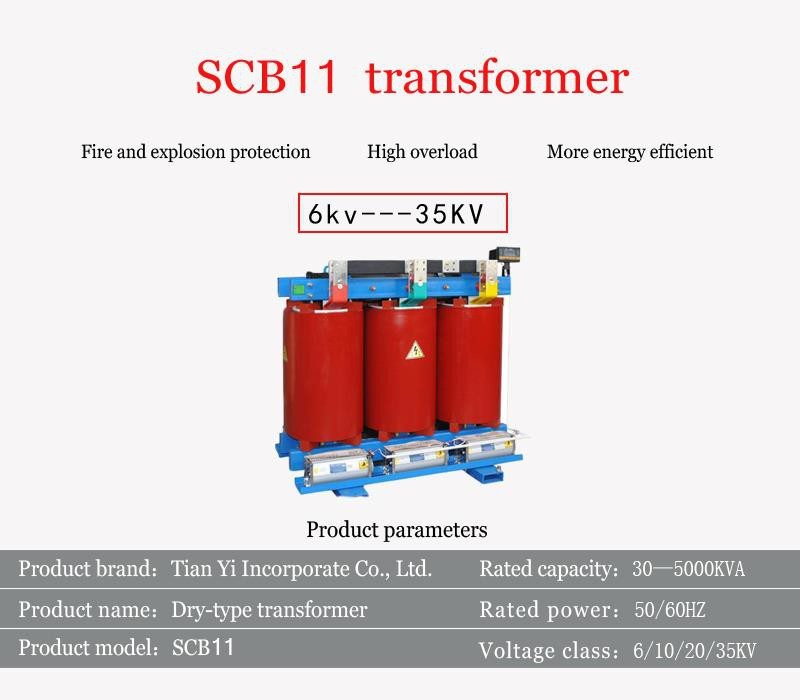

- Commodity name: Cast Coil Transformer Dry Type

The safe operation of dry-type transformers and their service life depend largely on the safety and reliability of the transformer winding insulation.

The safe operation of dry-type transformers and their service life depend largely on the safety and reliability of the transformer winding insulation.

Winding processing technology characteristics

The low voltage winding is made of copper foil and resin pre-impregnated insulation. After the winding is processed, the coil is put into an oven and solidified to make it a winding with a strong ability to withstand short circuits.Resin casting dry-type transformers are reasonably designed to use our high-quality materials and the most modern casting technology to make our products have a lower partial discharge.

In the production process, pouring is a key to ensure the best insulation and mechanical properties, and there should be strict process control. On the one hand, the windings are placed in a preheating furnace until the prescribed pouring temperature is reached. On the other hand, a resin mixing table is prepared in a continuously operating apparatus. The various components of the resin are only mixed together before pouring. After this, the preheated windings are transferred to the vacuum casting chamber. Once the degree of vacuum in the casting chamber reaches the specified value, the resin is poured into the mold. In this way, when the resin is poured into the mold, the viscosity of the mixed resin is very low. Can fill the gap. Thereby reaching the lowest partial discharge level. After pouring is completed. The winding is cured to the final good performance.

Related products

Communication and Support

Welcome to Tianyi Incorporate, if you are interested in our products, please submit your contact information and we will arrange a professional engineer to discuss with you as soon as possible!