High Reliability Substation Station Service Transformer

Keywords:

High Reliability Substation Station Service Transformer

Category:

产品描述

- 产品描述

-

- Commodity name: High Reliability Substation Station Service Transformer

Dry-type transformers are mainly divided into three types: open type, closed type and cast type. The safe operation of dry-type transformers and their service life depend largely on the safety and reliability of the transformer winding insulation. The safe operation and service life of dry-type transformers largely depend on the safety and reliability of the transformer winding insulation.

Technical Parameters

1. Using frequency: 50 / 60HZ;

2. No-load current: <4%;

3. Withstand voltage: 2000V / min without breakdown; Test instrument: YZ1802 withstand voltage tester (20mA);

4. Insulation grade: F grade (special grade can be customized);

5. Insulation resistance: ≥2M ohm Test instrument: ZC25B-1 type 4 megohmmeter <1000V);

6. Connection method: Y / Y, △ / Y0, Yo / △, auto-coupling (optional);

7. Allowable temperature rise of coil: I00K;

8. Cooling method: natural air cooling or automatic temperature control;

9. Noise figure: ≤30dB.Working environment

1. 0-40 (℃), relative humidity <80%;

2. Altitude: no more than 2500 meters;

3. Avoid being exposed to rain, moisture, high temperature, high heat or direct sunlight. The distance between the heat dissipation vent and the surrounding objects should be no less than 40cm;

4. Prevent working in places with corrosive liquids, or gas, dust, conductive fibers or metal fines;

5. Prevent working in the place of vibration or electromagnetic interference;

6. Avoid long-term upside down storage and transportation, and not subject to strong impact.

The safe operation and service life of dry-type transformers largely depend on the safety and reliability of the transformer winding insulation. It is one of the main reasons that the transformer can not work normally because the winding temperature exceeds the insulation withstand temperature and the insulation is damaged. Therefore, the monitoring of the operating temperature of the transformer and its alarm control are very important.1. Safety, fire prevention, no pollution, can be directly operated in the load center.

2. Adopt domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability and long service life.

3. Low loss, low noise, obvious energy saving effect and maintenance free.

4. Good heat dissipation performance, strong overload capacity, can increase capacity operation when forced air cooling.

5. Good moisture resistance, suitable for operation in high humidity and other harsh environments.

6. Dry-type transformer can be equipped with perfect temperature detection and protection system. The intelligent signal temperature control system can automatically detect and patrol the respective working temperatures of the three-phase windings, and can automatically start and stop the fan, and have functions such as alarm and trip.

7. Small size, light weight, small footprint and low installation cost.

Because there is no oil in the dry-type transformer, there is no fire, explosion, pollution, etc. Therefore, the electrical specifications and regulations do not require the dry-type transformer to be placed in a separate room. Losses and noise have been reduced to new levels, creating conditions for transformers and low-voltage screens in the same distribution room.Performance introduction

The core of the dry-type power transformer adopts high-permeability high-quality grain-oriented cold-rolled silicon steel sheet 45 ° full oblique step seam. The core adopts a special square tube pull plate structure. The core post is bound by insulating tape. Special resin coating to prevent moisture and rust, effectively reducing no-load loss, no-load current and core noise.

Dry-type power transformer is a kind of dry-type transformer with high electric strength, high mechanical strength. It is an excellent product for urban power grid transformation, especially suitable for high-rise buildings, airports, power stations, commercial centers and other important places that require fire protection, explosion protection, and moisture resistance.Advantage

1. Low loss, good power saving effect, brings economic benefits in the industry.

2. Flame retardant, explosion-proof, non-pollution, maintenance-free, can be installed in the load center decentrally, reducing investment costs and saving costs.

3. The partial discharge is less than 10PC, the coil does not absorb moisture, does not warm the dust, has high mechanical strength and good reliability.

4, Short-circuit resistance, good lightning shock resistance.

5. The shell is made of three materials: stainless steel, cold plate and aluminum alloy. The type is divided into wind type and heat dissipation type. Go in and out.

6. The transformer can be equipped with temperature control and temperature display system according to user needs, and can be used in conjunction with the temperature control system.1.High insulation strength

Pouring epoxy resin has an insulation breakdown field strength of 18-22KV / mm, and an oil-immersed transformer with the same voltage level has approximately the same lightning impulse strength. The insulation temperature level is F level, and the maximum allowable temperature is 155 ° C. The winding temperature The rise limit is 100K.

2.Strong short-circuit resistance

Due to the material characteristics of the resin, the winding is cast as a whole, and it becomes a rigid body after being heated and fixed. Therefore, the mechanical strength is very high, and it is proved by the short circuit test that the resin cast dry-type transformer is rarely damaged due to short circuit.

3.Outstanding disaster prevention performance

Epoxy resin is flame retardant, flame retardant and self-extinguishing, and will not cause secondary disasters such as explosion.

4.Superior environmental performance

Epoxy resin is a chemically and stable material that is moisture-proof and dust-proof. It can operate reliably even in harsh environments such as atmospheric pollution. Can be put into operation again.

5,Maintenance-free

Due to the perfect temperature control and temperature display system, the epoxy resin cast dry-type transformer can be maintenance-free at present, which can greatly reduce the burden on operating personnel and reduce operating costs.

6.Low operating loss and high operating efficiency

7,Low noise

8,Small size, light weight, convenient installation and commissioning

9. No separate transformer room is needed, no hanging core inspection is needed, saving floor space.

10.Strong overload capacity

When the ambient temperature is 20 ° C, it can be overloaded for 1.16 times in a long time and 1.5 times in 60 minutes. If the fan is put in and the transformer is operated under forced air cooling (AF), it can be overloaded for 1.5 times.Winding processing technology characteristics

The low voltage winding is made of copper foil and resin pre-impregnated insulation. After the winding is processed, the coil is put into an oven and solidified to make it a winding with a strong ability to withstand short circuits.

Resin casting dry-type transformers are reasonably designed to use our high-quality materials and the most modern casting technology to make our products have a lower partial discharge.

In the production process, pouring is a key to ensure the best insulation and mechanical properties, and there should be strict process control. On the one hand, the windings are placed in a preheating furnace until the prescribed pouring temperature is reached. On the other hand, a resin mixing table is prepared in a continuously operating apparatus. The various components of the resin are only mixed together before pouring. After this, the preheated windings are transferred to the vacuum casting chamber. Once the degree of vacuum in the casting chamber reaches the specified value, the resin is poured into the mold. In this way, when the resin is poured into the mold, the viscosity of the mixed resin is very low. Can fill the gap. Thereby reaching the lowest partial discharge level. After pouring is completed. The winding is cured to the final good performance.Product description:

10KV epoxy resin cast dry-type transformer can be used as the replacement product of oil-immersed distribution transformer. It is the best product among various types of dry-type transformers, especially suitable for urban power grids, high-rise buildings, business centers, theaters, Hospitals, hotels, tunnels, subways, underground power stations, laboratories, stations, terminals, airports, combined substations and other important places.Features:

10KV class low noise and low loss type resin wound coil dry-type transformer. Due to advanced design, high-quality materials, scientific formula, strict technology and high standard testing, the product has the following characteristics:

1. Copper wire for high-voltage winding, copper wire or copper foil for low-voltage winding, glass fiber felt filling and wrapping, casting under vacuum state with unfilled epoxy resin, solidified cylindrical body after curing, mechanical High strength, small partial discharge and high reliability.

2. Flame retardant, explosion-proof, no pollution to the environment. Insulation materials such as glass fiber wound coils have self-extinguishing characteristics, and no arc will be generated due to short circuit. The resin will not generate toxic and harmful gases under high heat.

3. The coil does not absorb moisture, and the core clamp has a special anti-corrosion protection layer, which can run in 100% relative humidity and other harsh environments. Discontinuous operation is not necessary.

4. High level of resistance to short circuit and lightning.

5. Thin resin layer inside and outside the coil, good heat dissipation performance. The cooling method generally uses natural air cooling. For any protection level transformer, air cooling system can be configured to improve short-term overload capacity and ensure safe operation.

6. Small size, light weight, small space occupation, low installation cost, no need to consider oil drainage pond, fire prevention and fire protection facilities and backup power supply.

7. Low loss, good power saving effect, economic operation, and maintenance free

8. Because there is no risk of fire and explosion, it can be installed in the load center decentrally and fully close to the fire point, thereby reducing the cost of the line and saving the cost of expensive low-voltage facilities.1. High safety: it does not support combustion during use, can be flame retardant, will not explode and release toxic gases, will not cause harm to the environment, other equipment and human bodies, and is not sensitive to humidity, dust and pollution; no partial discharge during operation And there is never the possibility of "cracking".

2. High reliability: Both high and low voltage coils are made of NOMEX insulation material, and are impregnated with H-level solvent-free impregnated paint several times by VPI vacuum pressurization equipment, and baked at high temperature for several times. The product is H-class (180 ℃), and the main insulation material is C-class (220 ℃). It has strong overload capacity and good short-circuit resistance. Under good ventilation conditions, allow 20% overload operation.

3. Energy saving and environmental protection: After the end of product life, steel, iron and other materials are easy to recycle; all used NOMX paper will not release toxic substances when burning; other insulating materials can degrade and not pollute the environment; low product loss, energy saving; low noise Flexible design.

Compared with oil-immersed transformers, dry-type transformers do not have problems such as fire, explosion, and pollution because they are free of oil.Structural characteristics of dry-type transformer

1. Safety, fire prevention, no pollution, can run directly in the load center;

2. Adopt domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, and long service life;

3. Low loss, low noise, obvious energy saving effect, maintenance-free;

4. Good heat dissipation performance, strong overload capacity, can increase capacity operation when forced air cooling;

5. Good moisture resistance, suitable for operation in high humidity and other harsh environments;

6. Dry-type transformers can be equipped with complete temperature detection and protection systems. Using intelligent signal temperature control system, it can automatically detect and patrol the respective working temperature of the three-phase windings. It can automatically start and stop the fan, and has functions such as alarm and trip;

7. Small size, light weight, small footprint, low installation cost.

Dry-type transformers are transformers whose cores and windings are not immersed in insulating oil. Because dry-type transformers have the advantages of strong short-circuit resistance, small maintenance workload, high operating efficiency, small size, and low noise, they are often used in places with high performance requirements such as fire protection and explosion protection. Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminal CNC machinery and other places.Due to advanced design, high-quality materials, scientific formula, strict technology and high standard testing, the product has the following characteristics:

1.High-voltage windings are made of copper wire, low-voltage windings are made of copper wire or copper foil, filled with glass fiber felt, and filled with epoxy resin without filler under vacuum. After curing, a solid cylindrical body is formed. Mechanical High strength, small partial discharge and high reliability.

2.Flame retardant, explosion-proof, and no pollution to the environment. Insulation materials such as glass fiber wound coils have self-extinguishing characteristics, and no arc will be generated due to short circuit. The resin will not generate toxic and harmful gases under high heat.

3.The coil does not absorb moisture, and the core clamp has a special anti-corrosion protection layer, which can run in 100% relative humidity and other harsh environments. Discontinuous operation is not necessary.

4.The resin layer inside and outside the coil is thin, and the heat dissipation performance is good. The cooling method generally uses natural air cooling (AN). For transformers of any protection level, air cooling system (AF) can be configured to improve short-term overload capacity and ensure safe operation.

5.Low loss and good power saving effect. Economical operation and maintenance-free.

6.High level of resistance to short circuit and lightning.

7.Small size, light weight, small floor space, low installation cost, no need to consider oil drainage ponds, fire prevention and fire protection facilities, and backup power supplies.

8.Because there is no danger of fire and explosion, it can be installed in the load center and close to the power point, thereby reducing the cost of the line and saving expensive low-voltage facilities.Performance Feature

1. Transformers are safe, fire preventive, free of pollution, and capable to be run directly in the load center.

2. Produced with the domestically advanced technology, transformers feature high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, and long service life.

3. Transformers feature low loss, low noise, obvious energy-saving effect,and are maintenance free.

4. Transformers feature good heat dissipation performance, strong over-load capacity, and higher running capacity at forced air cooling.

5. Transformers feature good moisture-proof performance and suitable forhigh humidity and other harsh environments.

6. Dry type transformers can be equipped with perfect temperature detecting and protection system. The intelligent signaling and temperature control system can automatically detect and display working temperature of three-phase windings, automatically start and stop the fan, and has the functions such as alarming and tripping.

7. Transformers feature small volume, light weight, small occupied space, and low installation cost.

The company is a comprehensive electrical equipment manufacturing enterprise integrating R & D and production of electrical equipment such as distribution transformers, intelligent switch cabinets and box-type substations.The epoxy resin cast dry-type transformer is made of high-quality materials, scientific formula, and adopts advanced production testing equipment in strict process. The product has the characteristics of high reliability and long service life. Depending on the use environment, shells with different protection levels can be configured or not. It can be used as a replacement product of oil-immersed transformer, suitable for high-rise buildings, commercial centers, airports, tunnels, chemical plants, nuclear power plants, ships and other important or special environmental places.

Safe, fireproof, non-polluting, can be directly operated in load center

High mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, and long service life

Low noise, low loss, obvious energy saving effect, maintenance-free

Strong overload capacity, good heat dissipation performance, can increase capacity operation when forced air cooling

Good moisture resistance, suitable for operation in high humidity and other harsh environments

Can be equipped with a complete temperature detection and protection system. Intelligent signal temperature control system can automatically monitor and display three phases

Light weight, small size, small footprint, low installation costThe reasons are as follows:Assured quality、On-time delivery、Direct selling from the manufacturer、No worries after purchase.

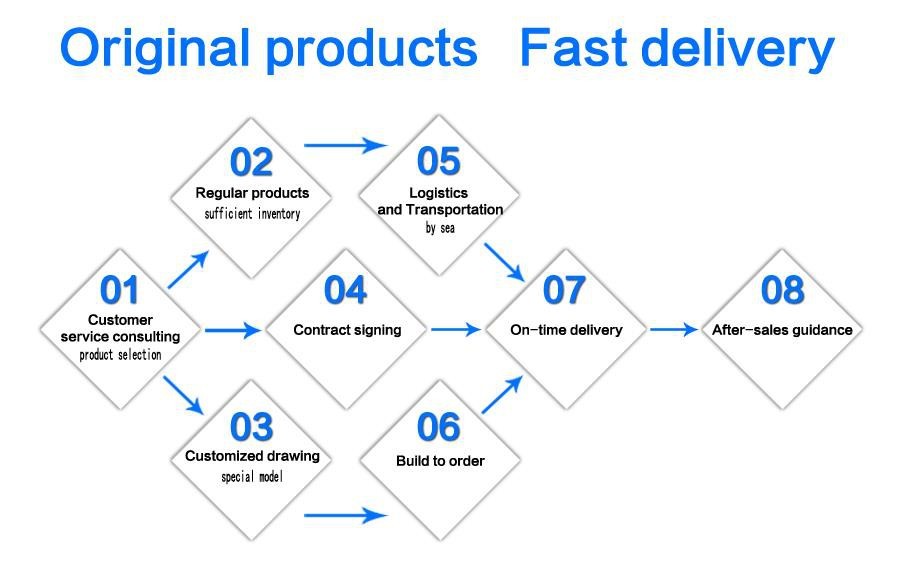

Production and customization of various transformers with a short construction period and guaranteed quality.

A Large production base of 10000 m², 600 sets of production inspection equipment, more than 300 front-line employees, and more than 50 technicians, with an annual output of more than 10,000 transformers, which have been sold to 32 countries.

After receiving user feedback, we will respond in 2 hours, make a solution in 4 hours, solve the problem remotely on video in 8 hours, and provide after-sales service on site in 48 hours.

Under the concept of customer focus and intimate user experience, Tian Yi Incorporate Co., Ltd. manufactures reliable power products and provides one-to-one customer service, which helps us understand customer needs faster and work out the transformer construction solution based on such needs.

If any problems occur during use, our technical team will identify the fault remotely on video within 4 hours and make a solution within 8 hours.

Original manufacturer of dry-type transformer

We guarantee not only the short lead time, but also the quality, safety and reliability

Related products

Communication and Support

Welcome to Tianyi Incorporate, if you are interested in our products, please submit your contact information and we will arrange a professional engineer to discuss with you as soon as possible!