3 Phase Unit Transformers Dry Type

Keywords:

3 Phase Unit Transformers Dry Type

Category:

产品描述

- 产品描述

-

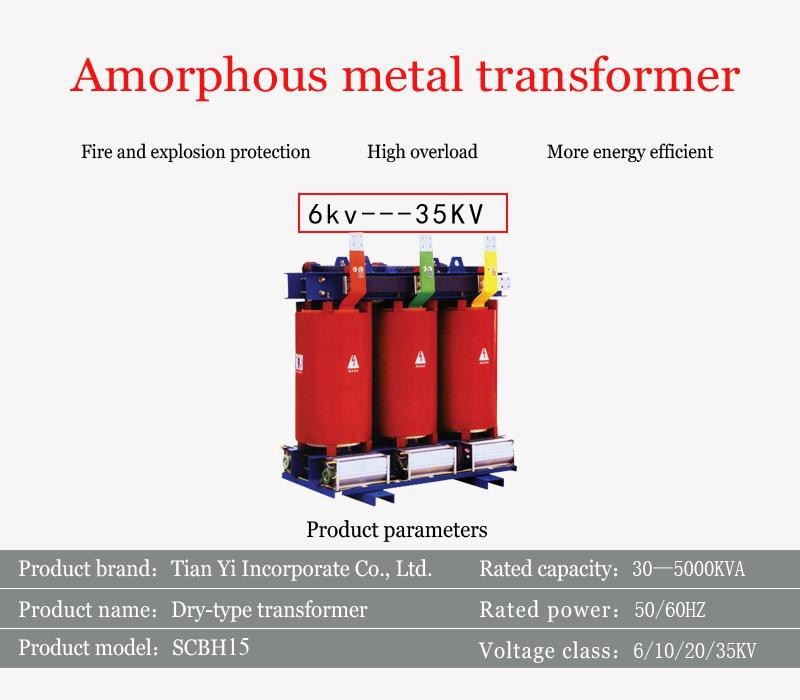

- Commodity name: 3 Phase Unit Transformers Dry Type

The resin mixture adopts two advanced foreign stirring methods and vacuum film degassing technology to make the mixture stir evenly and eliminate air bubbles in the mixture. The product has only a low partial discharge and can be controlled below 5PC.

Our company produces three-phase three-column amorphous alloy dry-type transformers, inheriting the advantages of cast-type dry transformers, with a more reasonable structure and more reliable performance.

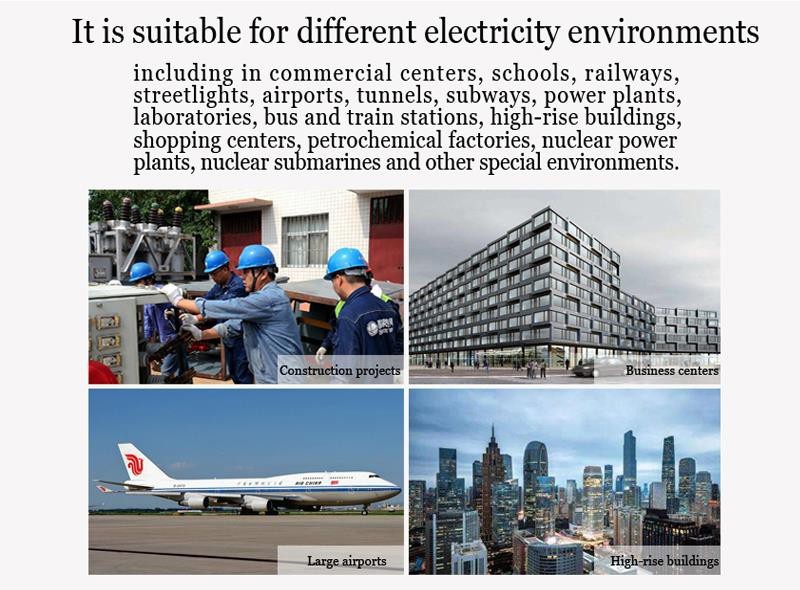

This product has the advantages of low no-load loss, no oil, flame retardant self-extinguishing, moisture resistance, crack resistance and maintenance-free. Every place that uses ordinary kaleidoscope can be replaced by amorphous kaleidoscope, which can be used in high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises and power plants. It is especially suitable for installation and use in places with high fire protection requirements such as flammable and explosive.

1. The product iron core is supported by the most advanced magnetically permeable material amorphous alloy, with superior performance, and its performance indicators have reached the international advanced level. The biggest feature of the amorphous alloy dry-type transformer: the no-load loss is one-third of the ordinary silicon steel sheet dry change, the energy saving effect is significant, and the product meets the national first-level energy efficiency standard.

2. Safety, flame retardant and fireproof, can be directly installed in the load center.

3. Maintenance-free, easy installation, and low comprehensive operation cost.

Low partial discharge: The resin mixture adopts two advanced foreign stirring methods and vacuum film degassing technology to make the mixture stir evenly and eliminate air bubbles in the mixture. The product has only a low partial discharge and can be controlled below 5PC. The high and low voltage coils are cast under vacuum and pressure, so that the resin insulation has both full encapsulation and inter-turn leaching. The casting body has a dense solidified structure, which is flame-retardant, explosion-proof, and does not pollute the environment.

Insulation materials such as glass fiber wound coils have self-extinguishing characteristics, and no arc will be generated due to short circuit. The resin will not generate toxic and harmful gases under high heat.

High mechanical strength: The resin with filler makes the expansion coefficient difference in the casting body small, the curing shrinkage rate is small, the internal stress is small, and the hardness of the cured product is high. The prefabricated reinforced material has a dense structure like reinforced concrete, so its mechanical strength is greater than that of pure epoxy resin, and it can withstand sudden short-circuit electric force without damage.

Related products

Communication and Support

Welcome to Tianyi Incorporate, if you are interested in our products, please submit your contact information and we will arrange a professional engineer to discuss with you as soon as possible!