High Efficiency Distribution Transformer

Keywords:

High Efficiency Distribution Transformer

产品描述

- 产品描述

-

- Commodity name: High Efficiency Distribution Transformer

The core limb is wrapped with epoxy fiberglass adhesive tapes and the core is assembled with tensile rods, side yoke clamping bolts and steel channel sections to apply clamping pressure, which ensures the overall rigid structure of the core, and at the same time the low loss and low noise of the product.

Product description:

The core limb is wrapped with epoxy fiberglass adhesive tapes and the core is assembled with tensile rods, side yoke clamping bolts and steel channel sections to apply clamping pressure, which ensures the overall rigid structure of the core, and at the same time the low loss and low noise of the product. The coil of each phase is subject to drying, compression, pressure test and height adjustment as per the process to ensure that the height of each coil meets the design requirements. The coils are dried with variable-pressure vacuum drying.

Applicable scope:

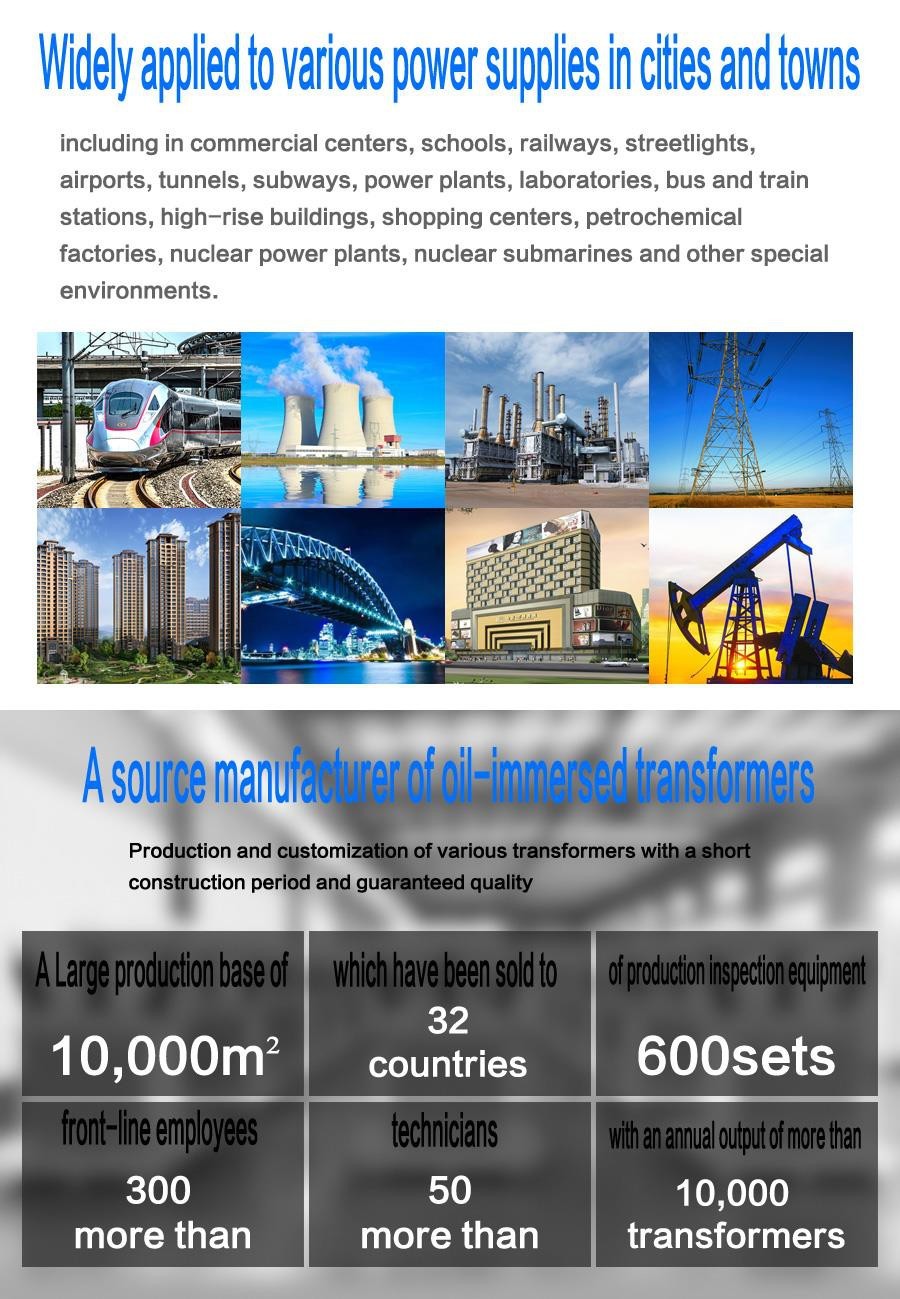

Including in commercial centers, schools, railways, streetlights, airports, tunnels, subways, power plants, laboratories, bus and train stations, high-rise buildings, shopping centers, petrochemical factories, nuclear power plants, nuclear submarines and other special environments.

Product model and designation:

Material:

The fully sealed and insulated shell is not easy to rust or corrode,Pure copper coil,Using new silicon steel sheets.

Logistics and Transportation:

by sea.

Delivery & Service:

Timely delivery each time. Provide reliable service and responsible for each customer with each product. Our target is to satisfy every customer with the best service.

Based on the S9 series, the no-load loss of the S11 series products has been reduced by an average of 20%; the energy-saving effect is significant, the new iron core material, mitred three-corner-joint structure and uniform magnetic circuit distribution greatly reduces the no-load exciting current and no-load loss, and the no-load current is reduced by 70-85% compared to S9; the average temperature rise is reduced by 10K, the service life of the product is more than doubled, and it can be operated for a long time even under the condition of 120% load; and the average operating noise is reduced by 2-4 dB. The high and low voltage windings, body assembly, oil tank structure, protection devices, etc. are similar to the S9 series transformers. Both do not adopt the core-lifting structure, but apply the vacuum drying, vacuum oil filtering and oil injection processes, and use the corrugated oil tanks, without conservator tank.

FAQ:

Q1: Can the price be negotiated?

Yes, the price is negotiable. It can be changed based on your quantity or packaging.Q2: What is the difference between the copper and aluminum cores of the transformer?

Aluminum coils have lower mechanical strength than copper coils. The aluminum wire has poor thermal stability, and the aluminum wire loop is easy to burn. The production cost of aluminum wire is lower than copper wire.Q3: What is the role of transformer oil?

Insulation, heat dissipation and arc suppression.

Related products

Communication and Support

Welcome to Tianyi Incorporate, if you are interested in our products, please submit your contact information and we will arrange a professional engineer to discuss with you as soon as possible!